Ghost Peaks in U/HPLC: Causes & Preventions

July 2, 2025

Author: Matt Boag

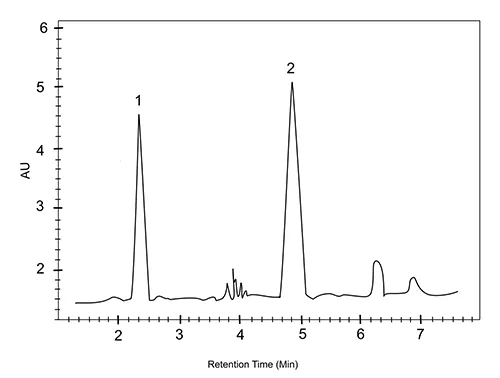

Ghost peaks are unexpected, unexplained signals in chromatograms that do not originate from known sample components. These anomalies can appear during both sample analysis and blank runs, making them difficult to trace and eliminate.

In U/HPLC, where high sensitivity and precision are essential, ghost peaks pose a significant challenge. They can interfere with data interpretation, compromise method development, and lead to inaccurate results, especially in critical fields like pharmaceuticals where measurement accuracy is vital.

Ghost peaks may arise in any liquid chromatography (LC) technique, including analytical, preparative, or specialized formats. Their unpredictable nature requires careful examination of chromatograms and thorough troubleshooting to identify and eliminate root causes.

Understanding and addressing ghost peaks is essential for maintaining data quality, reliability, and reproducibility in chromatographic analysis.

Common causes of ghost peaks

Ghost peaks can arise from multiple sources within the U/HPLC system. Pinpointing these factors is essential for effective troubleshooting of peak issues in HPLC. The common causes are:

Sample contamination

False signals may come from contamination during sample processing. Impurities remaining in the system after processing more samples can cause ghost peaks in later runs. Ghost peaks are significantly more problematic when the contaminants have retention times comparable to the analytes of interest.

Equipment malfunction

Difficulties with U/HPLC equipment can also cause ghost peaks. For instance, leaks in the pump or injector might allow air or other contaminants into the system, potentially causing baseline disruptions. Furthermore, malfunctioning detectors may generate noise that appears as ghost peaks.

Mobile phase impurities

Using unfiltered or low-quality solvents can introduce particulate matter into the system. This contamination can result in baseline noise or ghost peaks, especially when using sensitive detection methods like UV spectroscopy. Proper solvent preparation and filtration are essential to minimize this risk.

>External environmental factors

External factors like temperature fluctuations and electromagnetic interference can be some outer factors that are known to disturb the performance of U/HPLC. Changes in ambient conditions will destabilize baselines and, therefore, contribute to the formation of ghost peaks.

How to identify ghost peaks?

Identifying ghost peaks in chromatography, particularly in U/HPLC, involves a systematic approach to determine their origin and eliminate them. Ghost peaks can interfere with quantitation, and complicate analytical results. Here's a step-by-step guide to identify ghost peaks:

- Examining retention times: Ghost peaks are usually found on retention times that do not match any known analytes in the sample. Comparing the retention times with a blank run might help to narrow it down.

- Analyzing peak shape: Ghost peaks may have shapes that are irregular compared to sharp, well-defined analyte peaks. They may be broader or more diffuse due to their extraneous nature.

- Checking baseline stability: Baseline stability is essential for accurate peak identification. Sudden deviations in baseline levels may indicate the presence of ghost peaks.

- Performing blank runs: Running blank samples (without any analytes) helps to establish a baseline for comparison. Any unexpected peaks observed during blank runs are probably ghost peaks.

- Using controls: Analyzing known control samples that are free from contaminants helps to identify discrepancies that ghost peaks may cause.

By following these steps, analysts can effectively differentiate between actual analyte signals and ghost peaks, ensuring more reliable chromatographic results.

Related read: How to avoid ghost peaks in HPLC analysis

Methods for the elimination of ghost peaks

Eliminating ghost peaks involves a combination of preventive measures and corrective actions aimed at addressing their root causes. Here are several strategies:

Cleaning and maintenance of the system

Regular cleaning and maintenance of U/HPLC components such as injectors, columns, and detectors are essential to prevent contamination-related ghost peaks and ensure optimal system performance. Proper calibration and upkeep of the injector help maintain accurate and consistent sample volumes, while avoiding column overloading minimizes the risk of residual impurities and ghost peaks.

Solvent quality control

Using high-purity solvents that have been appropriately filtered and degassed minimizes the introduction of impurities into the system. Analysts should always check solvent quality before use and consider using certified reagents whenever possible.

Regular system checks

Regular checks for leaks and malfunctions in the U/HPLC should be performed to identify potential ghost peak causes early in the process. This monitors the performance and calibration of the equipment, ensuring consistent operation over time.

Temperature control

Maintaining a consistent temperature environment for both samples and equipment eliminates fluctuations that could cause baseline instability and ghost peak development. Implementing proper temperature controls is especially important in sensitive analyses.

By implementing these methods, laboratories can effectively reduce or eliminate ghost peaks in their chromatographic analyses, enhancing data quality and reliability.

FAQs

What role does the mobile phase play in ghost peaks?

The mobile phase significantly influences ghost peaks in liquid chromatography . Ghost peaks can arise from impurities in the mobile phase, which may include contaminants from solvents or air. Incomplete degassing of the mobile phase can also lead to dissolved gases forming bubbles, causing baseline disturbances that mimic peaks. Additionally, prolonged use of mobile phases without replacement can result in the accumulation of organic substances, further contributing to ghost peaks. To mitigate these issues, using fresh, high-purity solvents and ensuring complete degassing are essential practices.

Are ghost peaks specific to any LC analysis?

Ghost peaks are not specific to any single type of LC analysis but are particularly prevalent in gradient elution methods. They can arise from various sources, including impurities in the mobile phase, contamination from the LC system, or residual analytes from previous injections. These extraneous signals can interfere with the detection of actual analytes, making them a common concern across different LC applications, especially when analyzing low-concentration samples or clean solvents. Proper identification and mitigation strategies are essential to manage ghost peaks effectively in any LC setup.

How can you identify the source of ghost peaks?

To identify the source of ghost peaks in U/HPLC, the following steps should be taken:

- Blank injection: A blank run with the mobile phase alone should be performed. If ghost peaks appear, it can be concluded that they originate from the system rather than the sample.

- Compare peaks: The intensity and retention time of suspected ghost peaks should be analyzed against known sample peaks. Consistent peaks at the same retention time in both blank and sample injections indicate a ghost peak.

- Inspect system components: Contamination in the injector, column, or mobile phase should be checked, as residual impurities can cause ghost peaks.

- Evaluate method conditions: Proper method parameters (flow rate, temperature) should be ensured to avoid irregularities that may lead to ghost peaks.

- Monitor for equipment issues: Leaks or malfunctions in pumps and detectors should be looked for, as these could introduce noise or artifacts into the chromatogram.