Guest Author: Badaoui Omais, Ph.D.

How safe is it to inject water into your gas chromatography analysis?

The ability to inject water raises a lot of questions from

gas chromatography (GC) users. By discussing with our peers or wandering on GC websites, the four main questions that can be found are:

- Does water dissolve the GC stationary phase?

- Does water stick to GC columns?

- Are water samples incompatible with GC inlets?

- What about water wetability with GC phases?

Lost in the middle of all these rumors? Want to know the truth? Keep reading!

1.Does water dissolve the GC stationary phase?

This is both right and wrong! Today, you can inject water in most of the capilary phases because the phase is cross-linked to the silica. In fact all

Zebron® PolyDimethylSiloxe (PDMS) and PolyEthyleneGlycol (PEG) phases are cross-linked via :

- OH or O-CH3 termination for PDMS phases

- CO-Si for PEG phases

Thanks to this Engineered Self Crosslinkage technology (ESC), all columns represented in the MacReynolds scale below will not be subjected to phase dissolution.

On the contrary, old generation phases were simply coated onto the column and were not cross-linked. This is mostly the case of packed GC columns phases and first capillary GC columns.

Figure 1. MacReynolds classification of GC stationary phases

2. Does water stick to GC columns?

Going back to the GC principles, if the oven temperature is high enough (>120 °C), water will be eluted easily from the column. This works for all GC capilary columns mentioned in the MacReynolds scale above except one—the ZB-WAX™.

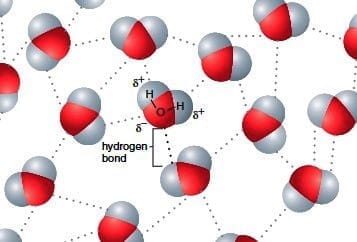

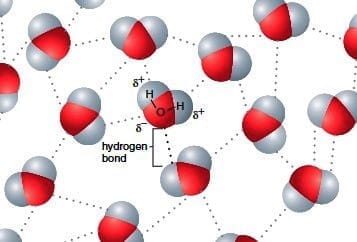

In fact,

WAX column phases are made of a PEG polymer, which will develop strong H-bonding interactions with water. Injection after injection, water molecules will adsorb and build up on the phase and lead progressively to a change of selectivity of the column. In addition, if the phase is not crosslinked properly, the uncrosslinked phase would bleed out with consecutive water injection. Retention times will therefore be shifted and the method will not be reproducible.

Figure 2. Hydrogen bonding interaction

If PEG phase is the most adapted selectivity for you, there is still a solution for your aqueous sample—the ZB-WAXPlus. This alternative to the ZB-WAX has similar selectivity, but its bonding process results in exceptional stability to repeated injections of aqueous matrices. Multiple or routine water injections will not alter the efficiency or polarity of the phase over time. This is the solution for many aqueous soluble compounds such as those found in

alcoholic beverages or glycol samples.

3. Are water samples incompatible with GC inlets?

While water samples are compatible with GC inlets, specific precautions must be taken due to the very important expansion volume of water.

As an example, 1.0µL of methylene chloride will only expand to 361µL in a 200°C inlet with a 10psi head pressure. Under the same conditions, 1.0 µL of water will expand to 1279µL.

Considering that liners have specific volumes, it is crucial to take this large expansion volume into account. In fact, if the expansion volume is larger than the liner volume, then the vapor can back-flush into the gas supply lines, which are not heated and cause persistent sample carryover. Small injection volumes are therefore recommended for water.

In fact, a standard Z-liner specification is 78.5mm length and 4mm ID. Its effective volume is therefore 493µL, which is way too low to contain the water vapor cloud under the conditions mentioned above.

4. What about water wetability with GC phases?

True! Contrary to most of the commercially-available WCOT stationary phases, water has a very high surface energy. Consequently, water has a very poor wetting property. The deactivation process used for column manufacturing, decreases the surface energy of the stationary phase. Therefore, the wetability could be enhanced, but the price to pay would be a very low inertness providing large peaks for active compounds (

Grob et. Al, J. Chrom. A; 473, 381-390 – 1989).

As water has a high boiling point and does not wet the phase well, some water can end up going through the column without being vaporized, resulting in peaks splitting and band broadening for highly water-soluble compounds.

The myth about water GC incompatibility is historical and comes from the old column technology, which were coated and not chemically bonded. Phenomenex only manufactures chemically-bonded columns that are all compatible with water. The only exception is ZB-WAX, which would show a low reproducibility after being used with water samples. In this case, its water-compatible version should be considered (ZB-WAXplus).

Most of the issues related to water injection actually come from volume expansion, which creates backflash. Decreasing the injection volume and the injection temperature would help you fix this.

Any questions? Live chat with our Technical Experts.

If PEG phase is the most adapted selectivity for you, there is still a solution for your aqueous sample—the ZB-WAXPlus. This alternative to the ZB-WAX has similar selectivity, but its bonding process results in exceptional stability to repeated injections of aqueous matrices. Multiple or routine water injections will not alter the efficiency or polarity of the phase over time. This is the solution for many aqueous soluble compounds such as those found in alcoholic beverages or glycol samples.

If PEG phase is the most adapted selectivity for you, there is still a solution for your aqueous sample—the ZB-WAXPlus. This alternative to the ZB-WAX has similar selectivity, but its bonding process results in exceptional stability to repeated injections of aqueous matrices. Multiple or routine water injections will not alter the efficiency or polarity of the phase over time. This is the solution for many aqueous soluble compounds such as those found in alcoholic beverages or glycol samples.