How to Choose the Right Column for Gas Chromatography: A Comprehensive Guide

July 24, 2025

Author: Duilio Romanello

Selecting the right gas chromatography (GC) column requires careful consideration of several key factors. The chemical nature of your target compounds—whether volatile, semivolatile, nonpolar, or polar—directly influences the choice of stationary phase. Column dimensions (length, internal diameter, and film thickness) also play a critical role, affecting resolution, sensitivity, and analysis time. Additionally, the stationary phase determines how analytes interact with the column, impacting retention time and selectivity. Ensuring compatibility with your detector and carrier gas is equally important.

By evaluating these elements together, you can tailor your GC setup to meet your analytical objectives. This guide will walk you through the selection process to help you achieve accurate, efficient, and application-specific results.

Types of Columns in GC

GC columns come in various types, each designed to handle specific analytical needs and sample characteristics. The two primary categories are packed columns and capillary columns, with further variations based on the stationary phase, dimensions, and material.

The choice between packed and capillary columns depends on the specific requirements of the analysis, such as sample size, the resolution needed, and the nature of the compounds being separated.

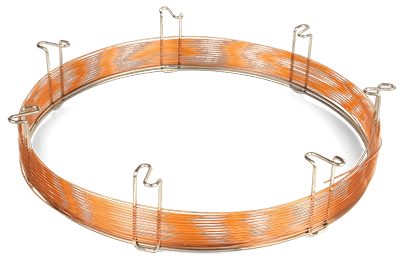

Packed GC Columns

Packed columns for GC, made of stainless steel or glass, are filled with solid or liquid stationary phases. They are often used for larger sample sizes, preparative work, and gas analysis. While packed columns are durable, cost-effective, and ideal for simple separations, they generally offer lower resolution and slower analysis compared to capillary columns but they offer a wide range of selectivities.

Capillary GC Columns

Capillary columns are the most common type. They are long and narrow, with a thin film of stationary phase along the inner wall. They provide high-resolution analysis of complex mixtures and are well-suited for trace-level detection and volatile compounds. Capillary columns come in several forms:

- Wall-Coated Open Tubular (WCOT)

WCOT columns are capillary columns with a thin layer of liquid stationary phase coated on the inner walls, offering high efficiency and excellent separation capabilities in GC. These columns are widely used for their durability, inertness, and ability to handle a broad range of analytical applications with precise temperature control. - Support-Coated Open Tubular (SCOT)

SCOT columns are capillary columns with a thin layer of solid support material coated with a liquid stationary phase, enhancing the surface area for interaction with analytes. This type of column offers improved capacity and efficiency compared to wall-coated columns, making them suitable for separating complex mixtures in GC. - Porous-Layer Open Tubular (PLOT)

PLOT columns are columns with a layer of solid adsorbent particles deposited on the inner wall, providing excellent retention for volatile compounds. They are widely used for applications such as hydrocarbon analysis and inert gas separation, offering fast analysis and durability, though careful manufacturing controls are necessary to prevent particle dislodgement.

Factors Affecting GC Column Selection

Choosing the right GC column requires careful consideration of various factors. Each factor plays a significant role in achieving effective separation and accurate analysis in gas chromatography applications.

Stationary Phase

The stationary phase is the heart of the GC column, dictating analyte retention and selectivity. The polarity of the stationary phase is crucial as it influences selectivity and separation efficiency. A stationary phase that closely matches the polarity of the target analytes enhances retention and resolution due to stronger intermolecular forces.

Column Dimensions

- Inner Diameter (ID): The diameter of the column affects sample volume capacity and sensitivity. Narrower columns offer higher efficiency, resolution and sensitivity but can be easily overloaded and require lower sample volumes, while larger diameters provide greater sample capacity at the cost of lower resolution.

- Length: Column length impacts retention time and separation efficiency. Longer columns enhance separation due to increased number of theoretical plates and more interaction time between analytes and stationary phase, but they, on the other hand, extend the total run time. Shorter columns allow for faster analyses but may compromise resolution.

Operating Conditions

Columns must withstand the temperature range required for the analysis. High-temperature columns are necessary for heavy or high-boiling compounds, while standard columns are suitable for most applications. The column’s thermal stability affects both performance and longevity.

Sample Size and Complexity

Complex samples with numerous components may require longer, narrower columns for enhanced separation. For larger sample volumes, packed or wide-bore capillary columns are preferable to avoid overloading and ensure accurate quantification.

Detector and Carrier Gas Compatibility

The column must be compatible with the chosen detector and carrier gas to ensure proper analyte transport and detection. For example, columns used with mass spectrometry (MS) require low bleed and high inertness. Helium, hydrogen, and nitrogen are common carrier gases, each affecting efficiency differently.

Specialty GC Columns

Specialty GC columns are designed to provide targeted selectivity for specific applications, such as blood alcohol analysis, fatty acid methyl ester (FAME) profiling, simulated distillation (SIMDIST), detailed hydrocarbon analysis (DHA), and pesticide screening.

Temperature-Programmed GC Columns

Temperature-programmed GC columns are designed to operate with a controlled increase in temperature during analysis, optimizing separation for complex samples with wide boiling point ranges. This type of GC column improves retention time, enhances efficiency, and is commonly used for screening new samples to obtain maximum compositional information in minimal time.

Troubleshooting GC Column Performance

Troubleshooting GC column performance is crucial for ensuring accurate, efficient, and reliable results. Many GC problems can be prevented if the column and system are maintained routinely. Common issues can often be traced back to the column itself, and addressing them promptly helps maintain performance and extend the column's lifespan.

- One common problem is baseline drift or noise, often caused by contaminated carrier gas, column bleed, or detector instability. To resolve this, using high-purity carrier gas, installing or replacing gas filters, conditioning the column at the recommended temperature, and checking for detector leaks or contamination can help restore stability.

- Poor peak resolution can occur due to column overloadcaused by incorrect column dimensions or an incompatible stationary phase. Solutions include reducing the sample size, increasing the split ratio, using a longer or narrower column, and ensuring the stationary phase aligns with the analyte properties.

- Tailing peaks may result from active sites on the column, poor sample quality, or improper column conditioning. Deactivating the column with a trim or chemical treatment, replacing the injection liner, and properly filtering and preparing samples can address this issue.

- Broad peaks may be caused by excessive sample size, slow injection, incorrect installation or poor thermal conductivity. Reducing injection volume, increasing the split ratio, reinstalling the column and ensuring proper column temperature and carrier gas flow rates are necessary fixes.

- A shift in retention time can be caused by inconsistent carrier gas flow, temperature fluctuations, or column degradation. To correct this, verify and stabilize carrier gas flow, maintain constant oven temperature, and replace aging columns as needed.

- If there are no peaks or a low response, it could indicate a blocked column, leak, or faulty injector/detector. Checking for leaks, cleaning or replacing the injector, and trimming the column to remove blockages should resolve this.

- Split or distorted peaks can result from inconsistent injections, poor sample vaporization, or uneven column temperature. Optimizing the injection technique, ensuring proper injector temperature, and verifying oven temperature uniformity are key solutions.

To prevent issues from arising, regular column conditioning, periodic trimming to remove degraded sections, and proper storage techniques—avoiding extreme temperatures or moisture—are essential. By systematically troubleshooting and maintaining the GC column, analysts can ensure consistent performance and achieve high-quality analytical results.

Review Manufacturer Guidelines

The GC column selection should include a thorough review of the guidelines provided by the manufacturer, which offer comprehensive recommendations tailored to specific applications, sample matrices, and method requirements. These guidelines are often associated with phase selection tables, compatibility charts, and performance specifications and serve as essential resources for aligning the column choice with precise analytical objectives.

Frequently Asked Questions

What type of GC column is best for volatile compounds?

For optimal results when analyzing volatile compounds using gas chromatography, choose a wall-coated open tubular (WCOT) column with a thicker film thickness, a small inner diameter, and a suitable stationary phase tailored to your specific analytes. This combination will enhance retention and improve separation efficiency while minimizing bleed and maximizing sensitivity. Standard phases for analysis of Volatile Organic Compounds (VOC) include ZB-624 phases, ZB-WAX phases and ZB-1 phases with ticker film.

How does the stationary phase affect column selection?

The stationary phase in GC primarily determines the selectivity of the column and retention characteristics, which influences the separation of analytes based on their chemical interactions with the phase. Selecting an appropriate stationary phase ensures optimal resolution and separation efficiency tailored to the specific properties of the sample components.

How do I maintain and extend the life of my GC column?

Regularly condition the column according to manufacturer guidelines to remove contaminants and ensure optimal performance. Prevent contamination by keeping the injector, septum, and liners clean, and using clean, filtered carrier gas. Proper storage is essential, so always cap the ends of the column and avoid exposure to extreme temperatures or moisture. Handle the column gently to prevent physical damage, such as kinks or bends. Additionally, periodically trim the column to remove degraded sections, particularly if the column is frequently exposed to high temperatures. Guard columns and liners packed with glass wool, can protect the column. By following these steps, you can prolong the lifespan of your GC column and maintain consistent, high-quality results.