The Role of Flow Splitters in GC Analysis

July 24, 2025

Author: Duilio Romanello

Gas Chromatography (GC) is a powerful analytical technique for separating and analyzing compounds in a mixture. A key component of a GC system that enhances performance is the flow splitter, which precisely controls flow, allowing portions to be directed to multiple detectors or paths. This improves both analytical precision and system flexibility.

What Are Flow Splitters and How Do They Work?

A flow splitter is an engineered device that regulates pressure and divides the flow stream into two or more pathways. This is especially valuable in split/splitless injectors, multi-detector setups, 2D-GC (GCXGC) applications, GC-olfactometry or complex analytical methods. In gas chromatography, its primary role is to manage how the sample is distributed in the injector—ensuring the appropriate portion reaches the column while the rest is either vented or routed elsewhere; it is also used to split flow path to multiple detectorsThe split ratio is critical, as it affects both sensitivity and resolution. For instance, directing more flow to a detector may boost sensitivity but reduce the sample available for other detectors, potentially impacting overall system performance.

Flow splitters typically feature precision components like splitter valves and capillaries that ensure consistent, stable flow across all paths. This uniformity leads to more accurate and reliable results across multiple detectors.

Key Components and Mechanisms

To understand the efficiency and precision of gas chromatography systems, it is essential to explore the key components and mechanisms that govern flow control and distribution within split injection systems.

Fixed vs. Adjustable Splitters:

- Fixed splitters in gas chromatography provide a constant and reliable split ratio—typically ranging from 1:1 to as high as 20,000:1—determined by internal fluid resistors. These splitters are not influenced by changes in solvent viscosity or system pressure, making them ideal for routine analyses that demand high reproducibility. Once installed, they require no calibration or adjustment, ensuring stable operation over time. The split ratio can only be changed by physically replacing the resistor cartridge or the splitter unit itself.

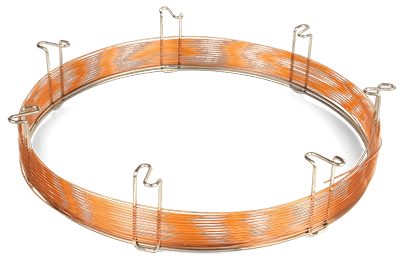

An example of a fixed splitter is the Y splitter, where the split ratio is set by the length and internal diameter of the restrictor tubing attached to each outlet. Since these dimensions define the flow resistance, the ratio remains fixed unless the tubing is manually replaced. - Adjustable splitters, on the other hand, offer the ability to change the split ratio in real time using mechanisms such as metering valves or adjustable resistors. They provide flexibility across a wide range of ratios (e.g., 1:1 to 20:1 or more) and are designed to maintain stability even during solvent composition changes or gradient runs. While they require periodic calibration and manual adjustment, their dynamic control makes them better suited for method development, multi-detector setups, and analytical scenarios where on-the-fly tuning is advantageous.

- Flow Restrictors: Calibrated capillaries or tubing that introduce resistance to control and proportion the flow of carrier gas. For example, a 10:1 split ratio directs ten parts of the flow to the vent and one part to the analytical column or detector.

- Pressure and Temperature Compensation: Advanced flow splitters—such as dome splitters—are designed to maintain stable performance by compensating for variations in temperature and pressure.

Optimizing Flow Splitter Settings

Optimizing the flow splitter settings of a GC flow splitter is of utmost importance for achieving maximum performance from a GC system. Well-adjusted splitter settings can enhance the system's sensitivity, avoid column contamination, and guarantee the detectors' performance.

The settings of a gas flow splitter are vital for the efficiency of the chromatographic process. Properly optimizing the flow splitter can help:

- Ensuring Split Ratio Stability During Temperature-Programmed GC Runs: Maintain consistent and reproducible split ratios throughout temperature-programmed runs by accounting for the temperature dependence of restrictors and system pressures, which is essential for quantitative accuracy and method robustness.

- Increase Sensitivity: Adjusting the flow splitter to direct more flow to detectors increases their sensitivity, allowing for the detection of trace amounts of substances.

- Ensure Proper Sample Distribution: A balanced flow split ensures that each detector receives the right amount of sample for accurate analysis.

- Increase Sensitivity: Adjusting the flow splitter to direct more flow to detectors increases their sensitivity, allowing for the detection of trace amounts of substances.

- Prevent Overloading Detectors: If too much of the flow is directed at a single detector, it may become overloaded, leading to poor results.

- Enhance System Performance: Proper flow splitting contributes to better peak shapes and resolution in chromatograms, improving the overall system performance.

- Working with difficult matrices: Adjusting the flow splitter helps to work with difficult matrices reducing the amount of sample that reaches the column.

Steps for optimizing flow splitter settings

Optimizing flow splitter settings is essential for achieving accurate, reproducible chromatographic results, particularly when handling variable sample compositions and dynamic system conditions.

- Set the Split Ratio: The split ratio plays a key role in balancing detector sensitivity and GC standard column longevity. Higher split ratios (e.g., 10:1) are ideal for dirty or complex samples, as they reduce the deposition of non-volatile residues on the column, thereby minimizing contamination where sensitivity is less critical. In contrast, lower split ratios are preferable when maximum sensitivity is required.

For example, a vent flow of 100 mL/min and a column flow of 2 mL/min would result in a split ratio of 50:1. This arrangement would have most of the sample flow going to waste and a small portion to the detector. - Maintain Appropriate Inlet Pressure: Inlet pressure affects flow rate and split ratio. Use pressure programming if necessary to stabilize flows during temperature ramps.

- Compensate Injection Volume: When increasing the flow rate (e.g., ramping flow from 100 µL/min to 570 µL/min), it is necessary to split the flow so that it matches the reduced analyte mass reaching the detector. The injection volume needs to be multiplied by the split ratio to maintain consistency in analyte detection.

- Validate with Detector Signals: After adjusting splitter parameters, it is essential to verify consistent splitting using detector signals. Significant timing delays or distorted peaks between split streams indicate the need for further splitter adjustments. Ideally, the timing lag should remain under five seconds to avoid peak broadening and ensure analytical accuracy.

Applications of Flow Splitters in GC

Flow splitters are a versatile component of various advanced gas chromatography technique applications. It shows multiple uses, including splitting the sample into multiple columns, splitting the column effluent into multiple detectors, and back-flushing or exchanging columns. Here are some of the most significant applications of flow splitters in GC systems, showcasing their adaptability and wide-ranging utility:

- Multi-Detector Analysis: In complex analytical workflows, multiple detectors are often used simultaneously to gain a more comprehensive understanding of the effluent. For instance, in GC-MS, a flow splitter can direct the effluent to both a mass spectrometer and a flame ionization detector (FID), enabling dual detection from a single injection. This approach increases analytical efficiency, reduces sample consumption, and enhances overall throughput.

Multidimensional Separations (GC×GC):

- Dean’s Switch Applications: Splitters facilitate comprehensive two-dimensional GC by modulating effluent transfer between columns. Auxiliary gas flows precisely control heart-cutting for enhanced resolution of complex mixtures.

- Backflushing: Integrated in 4-port splitters to remove heavy matrix components, reducing column contamination and analysis time.

- GC-Olfactometry: In GC-olfactometry (GC-O), utilized to detect odor-active compounds, a flow splitter splits the effluent to a conventional detector (e.g., FID) and a human sniffing port. This enables odor compounds to be identified by chemical detection and human sensory analysis.

Challenges and Solutions with Flow Splitters

Although flow splitters are vital to GC systems, they can present certain challenges. Recognizing these potential issues and knowing how to address them is key to optimizing performance and ensuring reliable analysis.

Temperature-Dependent Split Ratios

- Problem: Fixed flow restrictors tend to be unable to produce a stable split ratio during temperature ramps due to the temperature-dependent change in gas viscosity.

- Solution: To overcome this, dome splitters can be employed. These splitters dynamically adjust the restrictor dimensions in real time using integrated physical models to keep the split ratio stable, even with temperature fluctuations.

Inertness and Leakage

- Problem: Compounds such as polyimide or graphite ferrules can leak or shed contaminants under heat stress, corrupting the analysis.

- Solution: Incorporating metal ferrules in flow splitters provides a more inert, leak-free system.

Detector Compatibility

- Problem: When working with multiple detectors, e.g., mass spectrometers (MS) under vacuum, the flow splitter must provide for no backflow from atmospheric detectors.

- Solution: To avoid this, make-up gas lines and pressure-balancing tees are frequently incorporated into flow splitters. These devices ensure that pressure is constant throughout all detectors, avoiding backflow and proper operation.

High Split Ratio Instability

- Problem: Split ratios greater than 20,000:1 may become unstable, particularly in preparative chromatography, causing flow fluctuations that can compromise the analysis.

- Solution: Multi-stage splitters with serial dilution (e.g., two restrictors in series) contribute to improved stability for such high split ratios. These systems allow more stable flow division at extreme ratios, and the analysis remains consistent and accurate.

Frequently Asked Questions

Can flow splitters affect the sensitivity of detectors?

Yes, flow splitters can impact detector sensitivity in gas chromatography (GC), as dividing the effluent means each detector receives less analyte. This reduction can lower sensitivity, especially for detectors requiring low flow rates, such as mass spectrometers or thermal conductivity detectors. Introducing make-up gas or adjusting split ratios can help mitigate this by maintaining consistent sample transfer and minimizing peak broadening. Proper calibration and optimization are essential to ensure reliable detection performance.

What maintenance is required for flow splitters in GC systems?

Maintenance of flow splitters in GC systems involves regular cleaning and replacement of components to ensure optimal performance. Key tasks include inspecting and cleaning the split line to prevent blockages, replacing split vent traps every six months or more frequently for dirty samples, and checking for leaks around inlet seals and septum. Additionally, the split vent filter should be replaced periodically to avoid contamination that can affect quantitative accuracy and peak quality. Proper maintenance minimizes downtime and ensures consistent analytical results.

Are flow splitters suitable for all types of GC analyses?

Flow splitters are not universally suitable for all types of GC analyses. Their applicability depends on the specific analytical requirements, such as sensitivity, sample complexity, and detector compatibility. For applications requiring high sensitivity, flow splitters may reduce the analyte concentration reaching the detector, potentially affecting results. They are ideal for multi-detector setups or complex analyses where effluent splitting enhances efficiency and flexibility. However, careful optimization of split ratios and system design is necessary to ensure consistent performance without compromising data quality.