Headspace Gas Chromatography: Principles and Applications

August 7, 2025

Author: Duilio Romanello

Headspace gas chromatography (HS-GC) is a specialized technique for analyzing volatile compounds in complex matrices by sampling the gas phase above a solid or liquid sample. It minimizes interference from nonvolatile residues and simplifies sample preparation, making it ideal for diverse applications ranging from pharmaceuticals to environmental testing. HS-GC is a widely used technique for analyzing residual solvents in drug products formulations due to its enhanced sensitivity and lower maintenance compared to direct injection GC.

Headspace GC analysis extends column life and improves reproducibility by introducing only volatile compounds into the system. The process involves sealing a sample solution in aHS vial, allowing the liquid and the gas phase to reach equilibrium, and then injecting a portion of the headspace gas into the chromatograph for analysis.

Importance of HS-GC in Analytical Chemistry

Widely adopted for the analysis of volatile compounds, headspace gas chromatography provides several distinct advantages:

- Compatible with a wide range of sample matrices, including those that are non-volatile or insoluble.

- Requires minimal sample preparation, reducing the risk of error and improving reproducibility.

- Produces smaller solvent peaks, minimizing interference and resulting in cleaner chromatograms.

- Enhances instrument uptime by reducing the risk of contamination.

- Delivers high sensitivity with excellent precision and linearity.

Principles of Headspace Gas Chromatography

The term “Headspace” refers specifically to the vapor phase above a solid or liquid sample sealed in a container. HS-GC combines a headspace sampler and a gas chromatography system.

Headspace gas chromatography principle involves heating a sample in a sealed vial to vaporize its volatile components, which then accumulate in the headspace above the sample. These vapors are withdrawn through a needle and injected into the GC column for separation.

Within the column, analytes are separated based on their interactions with the stationary phases, each yielding a unique retention time. For accurate identification and quantification, it is essential to run both test samples and standards under consistent conditions.

Types of Headspace Gas Chromatography

Headspace gas chromatography techniques are categorized into two primary sampling methods-static and dynamic-each suited for specific analytical needs.

Static Headspace (Equilibrium Headspace)

Static headspace GC is a sample preparation technique used to analyze volatile compounds in solid and liquid samples by introducing only the gas phase above the sample into the GC column.

During preparation, the sample is placed in a sealed vial with headspace and heated, allowing volatile analytes to vaporize. Once equilibrium is reached between the sample and gas phase, the analytes are ready for analysis. The distribution of analytes between the phases is described by the partition coefficient, which is the ratio of their concentrations in the sample and gas phase.

Conventional headspace analysis typically detects analytes at concentrations from parts per billion (ppb) to low percentage levels, while trapping techniques allow for even lower detection limits.

Dynamic Headspace (Purge and Trap)

The term “headspace GC” often refers to static headspace but can also include dynamic headspace, known as purge and trap.

In purge-and-trap, an inert gas is bubbled through the sample to transfer volatile analytes to an adsorbent trap, commonly filled with materials like silica gel or activated charcoal. The trap is then heated to release the analytes into the gas chromatograph and further heated to remove residual compounds and moisture.

Dynamic headspace generally offers lower detection limits than static headspace because it can extract nearly all analytes from the sample matrix. However, advances in headspace sampler technology have narrowed the detection limit gap between static and dynamic techniques. Purge-and-trap systems typically require more maintenance and can encounter issues like sample foaming.

Solid-Phase Microextraction (SPME)

SPME is a solvent-free technique developed to analyze volatile and semi-volatile compounds in headspace and aqueous samples.

It works by using thermal desorption to extract analytes from the gas phase above a sample or directly from the liquid phase. The core of the method involves a thin fused silica rod coated with a specialized absorbent polymer, which is mounted on a metal rod to form the SPME fiber assembly.

These fiber assemblies are available in various polymer coatings and thicknesses, tailored to different analytical needs. Some fibers also incorporate adsorbent materials, such as those related to activated carbon, while most absorbent polymers are silicone-based, like stationary phases used in gas chromatography.

Components of a Headspace Gas Chromatography System

The components required for the headspace GC analysis are:

Carrier gas system

The carrier gas system in gas chromatography consists of a gas source, purification traps (such as hydrocarbon, oxygen, and moisture traps), and flow control mechanisms to ensure the delivery of clean and stable gas.

Commonly used inert gases include helium, nitrogen, hydrogen and argon. The selection of carrier gas depends on factors such as detector compatibility, desired resolution, cost, and safety. For instance, helium provides good resolution, speed and safety but is more expensive than other options. Hydrogen provides the fastest analysis and highest separation efficiency, but its use requires appropriate safety measures. Flow rate is a critical parameter, as it directly affects both the speed of analysis and separation efficiency—higher flow rates reduce run time but may compromise analyte resolution.

Sampler

Sampling and sample preparation are vital for achieving accurate and reliable gas chromatography (GC) results, especially when analyzing trace or ultra-trace levels of analytes in complex matrices.

Introducing unprocessed samples directly into the GC system can contaminate the inlet and column, leading to reduced performance and compromised data quality. To avoid these issues, proper preparation techniques—such as extraction, cleanup, and concentration—are necessary to ensure analyte compatibility with the system and enhance detection sensitivity.

Injector

The sample is fed into the column through the injector. Manual injection introduces significant variability in quantification, especially when different operators or multiple injections are involved. Key issues include premature vaporization of the sample, incomplete plunger depression, and inconsistent syringe handling, all of which can lead to inaccurate and non-reproducible results.

Syringe injection is a widely used and reproducible method for headspace sampling in GC. In this technique, the syringe is pre-heated to extract an aliquot of vapor from the headspace, which is then injected directly into the GC. To prevent condensation and sample carry-over, the syringe is kept slightly hotter than the oven and is flushed with carrier gas after each injection.

Column

The GC column plays a critical role in separating components of a mixture based on their interactions with the stationary phase. Selecting the appropriate column depends largely on the polarity of the sample to achieve optimal separation.

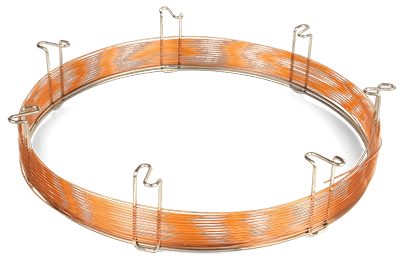

GC columns come in two main types: packed and capillary. Packed columns, typically made from metal or glass tubing, contain solid support materials coated with the stationary phase. Capillary columns, constructed from stainless steel or fused silica (quartz), have much narrower diameters and greater lengths, offering higher efficiency and resolution.

Separation occurs as analytes pass through the column and interact with the stationary phase. Compounds with stronger interactions move more slowly, while those with weaker interactions travel faster. As a result, analytes are separated based on the time they spend in the stationary phase relative to the temperature of the oven.

Detector

Once analytes are separated within the GC column, they enter the detector, which converts their presence into electronic signals that produce a chromatogram. Detectors differ in their selectivity—some respond to a broad range of compounds, while others are tailored to detect specific functional groups or elements.

Various types of detectors are used in gas chromatography, but the Mass Spectrometer (MS) is among the most preferred due to its capability to accurately identify and quantify unknown compounds with high sensitivity and specificity.

Headspace gas chromatography with flame ionization detection (FID) is also common for quantifying organic solvent residues.

Applications of Headspace Gas Chromatography

- Headspace analysis helps in detecting the quality of drinking water.

- Static HS-GC includes testing for blood alcohol, residual solvents in pharmaceuticals, and flavors in food.

- Purge-and-trap gas chromatography is used for flavor analysis in food and for detecting toxins in biological fluids.

- SPME is commonly used to detect pesticides and volatile compounds in environmental samples. It is also applied in the analysis of drugs in biological fluids.

- Headspace gas chromatography mass spectrometry (HS-GC-MS) has been effectively applied in the pharmaceutical industry for trace-level quantification of nitrite in excipients and chemicals, addressing concerns over nitrosamine formation.

- Gas chromatography solutions encompass a wide range of these techniques, offering reliable, sensitive, and efficient methods for analyzing volatile and semi-volatile compounds across various industries.

FAQs

How does HS-GC work?

HS-GC works by analyzing the volatile compounds present in the gas phase (headspace) above a liquid or solid sample sealed in a vial. The sample is heated to allow volatile analytes to equilibrate between the sample and the headspace, and then a portion of the headspace gas is injected into the gas chromatograph. Inside the GC system, the analytes are separated based on their chemical properties and detected for qualitative and quantitative analysis.

What industries use HS-GC?

HS-GC is widely used in pharmaceuticals for detecting residual solvents and impurities in drug formulations. It is also employed in the food and beverage industry to analyze flavors, contaminants, and packaging interactions. Additionally, environmental and forensic laboratories use HS-GC to monitor pollutants, toxic compounds, and substances in biological samples.

What types of samples can be analyzed using HS-GC?

HS-GC can analyze various sample types, including liquids, solids, and semi-solids that release volatile compounds. Common examples include pharmaceuticals, food products, biological fluids, and environmental samples like soil or water. The technique is especially useful when the analytes of interest are volatile and present in trace amounts within complex matrices.