GC Technical Tip

Level: Intermediate

How to Protect Your GC Column - Part 2

Welcome back to the topic of protecting your GC column! If you missed part 1 or would like to refresh your knowledge, find further tips on GC column protection here.

Protecting your GC column and instrument components from exposure to dirty samples or contaminants is important. Non-volatile or high molecular weight components can contaminate the stationary phase, causing poor peak resolution, lower accuracy, and poor column lifetime. Cutting off the damaged portion of column tubing will often restore your column’s performance, but over time performance will degrade to a point where the column can no longer be used. If you are experiencing rapid degradation of column performance, there are several simple ways to help protect your column and increase its lifetime.

Use A Liner With Wool

The liner is the first line of defense for your column, and the style you choose can make a big impact in how much contamination gets onto the column. The easiest thing to do is to add a small amount of silanized glass wool to a liner, which traps the non-volatile compounds and prevents them from entering directly into the column. Caution: glass wool can also add activity for acids, bases, and pesticides. Crushing the glass wool can expose undeactivated glass and free silanols (-OH groups) even if the wool has been deactivated. This leads to increased activity, so pre-packed liners, rather than self-packed ones are highly recommended to avoid reproducibility issues.

In addition to choosing a liner with wool, ensure that your liner (and other system consumables) are free of contaminant build-up that may form over time. Septum cores and other particulates that remain can become trapped in the wool and are sometimes difficult to spot. Regularly replace the liner (and other system consumables as needed) to reduce troubleshooting and maintenance.

Bake Out Your Column

The easiest way to reduce column contamination is to add a short, high temperature bake-out at the end of your standard GC method. This bake out helps remove high boiling contaminants that would otherwise remain in the column and cause damage. To bake out, the final oven temperature needs to be set high enough to ensure elution of these compounds, but not so high as to cause thermal damage. This can be done either isothermally, or more commonly, via an oven ramp until the last components elute from the column. Caution: NEVER exceed the upper temperature limits of your column. DO NOT exceed more than fifteen minutes at the upper isothermal temperature limit specified for the column.

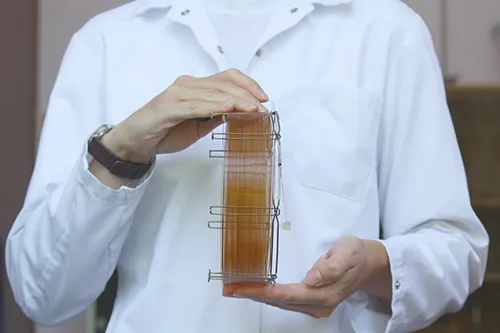

Zebron GC Columns

Explore our wide range of GC capillary columns and application-specific proprietary phases for environmental, food and cannabis, forensics, pharma, fuels, and specialty chemicals analyses.

- Low bleed

- Excellent retention

- High sensitivity

- Extended lifetime