What is Temperature Programming in Gas Chromatography?

August 12, 2025

Reviewed by Duilio Romanello

Temperature programming in gas chromatography (GC) is a mode of operation in which the temperature of the column oven is gradually increased during the separation process. This approach is used to enhance the resolution of compounds that have a wide range of boiling points and retention times, improving peak shapes and reducing analysis time.

The gradual temperature increase enhances separation efficiency, resolution, and sensitivity, allowing for precise control over analyte behavior. This capability transforms the separation process, streamlining analysis times and elevating overall performance.

Why is Temperature Programming Used?

- Allows efficient separation of complex mixtures containing both low and high boiling compounds.

- Compounds elute faster at higher temperatures, reducing overall run time.

- Prevents peak tailing and broadening that occur when using a constant temperature (isothermal) method.

- Compounds that would normally co-elute at isothermal conditions are better resolved.

How Temperature Affects Gas Chromatography?

Temperature significantly influences analyte separation and overall system performance. Its effects are profound and can be categorized into three main areas:

Vaporization of Analytes

For effective gas chromatography, analytes must transition from their liquid or solid states into the gas phase. This vaporization process, facilitated by elevated temperatures, is vital for achieving efficient separation, particularly for volatile compounds.

Inadequate vaporization can severely compromise separation efficiency, resulting in poor chromatographic outcomes. Optimal temperature ensures a balance between vaporization and condensation, allowing sufficient interaction with the stationary phase.

If temperatures are too low, analytes may remain condensed; conversely, excessively high temperatures can lead to complete vaporization without adequate interaction. Achieving this dynamic equilibrium maximizes resolution and sensitivity, ultimately leading to more reliable and accurate analytical results.

Partitioning Behavior

Temperature influences how analytes partition between the stationary phase and the carrier gas by affecting their vapor pressure. As temperature rises, volatile compounds move through the column more quickly due to increased vapor pressure.

Consequently, volatile compounds exhibit shorter retention times at elevated temperatures, allowing them to traverse the column more quickly.

Adjustment of Retention Time

Retention time, the duration an analyte spends in the column, is significantly affected by temperature. As column temperature increases, retention times for less volatile compounds typically decrease. Higher temperatures enable analytes to move through the column more rapidly; an increase of approximately 30°C can halve the retention time for some compounds. This reduction in retention time not only accelerates analysis but also enhances overall efficiency, making it possible to analyze samples more quickly without sacrificing resolution.

Related reads:

Advantages of Temperature Programming in Gas Chromatography

Temperature programming in gas chromatography presents several significant advantages that enhance analytical performance:

- Improved resolution: Variation in temperature with the analysis enables chromatographers to vary elution times for compounds. This dynamic adjustment can result in better separation of a closely eluting peak, thus enhancing resolution and results. For example, increasing the temperature can significantly reduce retention times for less volatile components, facilitating their separation from higher-boiling substances.

- Increased selectivity: Temperature programming allows for the fine-tuning of interactions between analytes and the stationary phase. By adjusting the temperature, chromatographers can enhance selectivity, making it easier to differentiate between compounds with similar chemical properties..

- Efficient analysis of complex mixtures: Temperature programming is very useful in the analysis of complex mixtures containing a variety of compounds with different boiling points and polarities. This technique allows for the simultaneous separation and analysis of multiple components in one run, thus improving efficiency.

- Faster analysis times: By optimizing the temperature ramp, temperature programming can significantly shorten analysis times. This is especially advantageous in applications requiring rapid results, such as quality control and process monitoring.

- Versatility: The flexibility of performing different temperature profiles, be it a continuous ramp or stepwise change, offers analysts an extended versatility in method development and allows the analyst to find the optimal conditions for any specific analytical requirement.

Key Requirements for Effective Temperature Programming

To effectively implement temperature programming in gas chromatography , several requirements must be met:

Selection of the Column

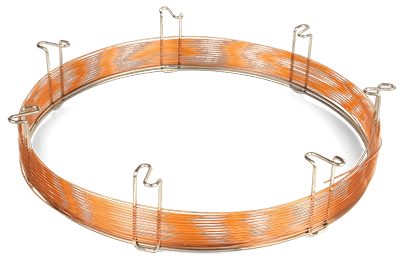

The GC column selection is an integral part of the temperature programming setup process. The column must withstand temperature variations without influencing the stationary phase and so hindering the separation process. Effective separation also mandates the selection of a column that is compatible with specific analytes, both in terms of column dimensions, stationary phase properties, and temperature requirements.

Stable and Precise Thermal Control

A reliable GC oven is required to maintain consistent temperature conditions during the analysis. The oven must be able to increase or decrease the temperature at a regulated rate while maintaining precise values as needed. If temperatures fluctuate, the separation and retention times may be affected, including the results obtained.

Method Development and Optimization

Effective temperature programming necessitates meticulous method development and optimization. It is essential to determine the optimal temperature ramps, hold times, and both initial and final temperatures tailored to a specific sample. This process often requires iterative optimization, as certain compounds may necessitate prolonged exposure to lower temperatures or a more accelerated temperature ramp to achieve effective elution. The goal is to create a temperature program that strikes a balance between separation efficiency and analysis time, ensuring that each analyte is effectively separated while minimizing the overall duration of the analysis.

Troubleshooting Temperature Programming Issues

Despite its advantages, temperature programming can present operational challenges that require targeted troubleshooting to ensure consistent and reliable results.

Poor Peak Resolution

If peaks are not well-separated, it is essential to adjust the temperature ramp rate or modify the temperature range. A slower ramp rate can provide more interaction time between analytes and the stationary phase, enhancing resolution. If issues persist, fine-tuning the initial and final temperatures may yield significant improvements.

Baseline Noise

Elevated baseline noise can obscure chromatographic peaks, complicating analyte detection. This issue can often be resolved by smoothing out temperature transitions to avoid abrupt fluctuations that contribute to noise. Additionally, using gas filters and ensuring proper calibration and functionality of all GC components is vital.

Retention Time Variability

Consistent retention times are crucial for reproducibility. Variations may indicate underlying issues with heating sources, column performance, or the method robustness. . Regular maintenance and checks on temperature accuracy can mitigate retention time drift. Adjusting the temperature program to account for column degradation and system drift over time is also advisable.

FAQs

Can temperature programming be used for all types of GC applications?

Temperature programming is widely used in gas chromatography, but it is not suitable for all applications. It excels in analyzing complex mixtures with varying boiling points, enhancing resolution and selectivity. However, for simpler mixtures or thermally labile compounds, isothermal conditions may be more effective. Additionally, temperature programming is particularly beneficial in capillary GC, where precise temperature control can significantly improve separation quality. Finally, the choice of temperature programming is determined by the specific analytical requirements and the nature of the samples to be analyzed.

Are there any limitations to using temperature programming in GC?

One primary concern is the potential for column bleed, where the stationary phase degrades at higher temperatures, affecting sensitivity and resolution. Additionally, maintaining consistent temperatures in the injector and detector is crucial but can complicate instrument design. Furthermore, not all analytes respond well to temperature changes; thermally labile compounds may degrade under elevated temperatures. Lastly, if not appropriately optimized, temperature programming can lead to band broadening, which negatively impacts peak resolution and detection limits.