Kinetex Core-Shell Technology Columns

The Core-Shell Advantage

Kinetex Core-Shell Technology delivers dramatic improvements in efficiency over conventional fully porous media, which can be leveraged to increase resolution, significantly improve productivity, reduce solvent consumption, and decrease costs. Whether you are running high-performance liquid chromatography (HPLC) or ultra-high performance liquid chromatography (UHPLC) methods, the Kinetex core-shell family can deliver shockingly improved performance over the current column you are using. Phenomenex designs, manufactures, and sells its very own silica and organo-silica core-shell particles.

Advantages of Kinetex HPLC Columns

- Performance gains on ANY liquid chromatography system

- System-to-system and lab-to-lab method portability

- Improve the productivity of older, established methods

How Does Core-Shell Technology Work?

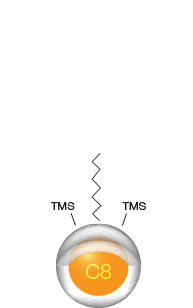

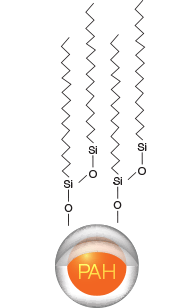

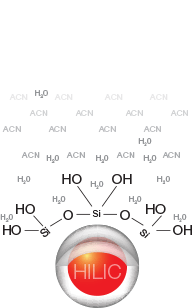

Core-shell technology in chromatography is a revolutionary approach that enhances the efficiency of HPLC systems while minimizing costs. Core-shell particles are designed with a solid, non-porous silica core surrounded by a porous outer layer. This unique structure allows for faster analyte mass transfer between the mobile and stationary phases, as diffusion occurs only through the thin, porous shell rather than the entire particle. This minimizes band broadening, leading to higher separation efficiency and sharper peaks.

The consistency in size and shape of core-shell particles further enhances separation efficiency by reducing variability in analyte movement. As a result, core-shell HPLC columns provide high efficiency and resolution at lower backpressures, making them an ideal choice for labs looking to improve their existing HPLC systems without the need for costly UHPLC equipment.

Core-shell technology thus offers a cost-effective alternative to upgrading to UHPLC systems, enabling labs to maximize the efficiency of their current HPLC setups. The formation of these particles through advanced sol-gel processing techniques ensures uniformity and reliability, making them a valuable tool in modern chromatography. By using the Kinetex HPLC column, laboratories can achieve faster analysis times and higher productivity while maintaining excellent separation performance.

Kinetex Core-Shell Performance on Any LC System

Particle Chemistry

Using sol-gel processing techniques that incorporate nano-structuring technology, a durable, homogeneous porous shell is grown on a solid silica core to create a Kinetex Core-Shell particle. This particle morphology results in less band broadening for all four sources of UHPLC band broadening compared to fully porous particles and thus delivers extremely high efficiencies.

- Optimized for Ultra-High Performance

- Superior Core-Shell Quality

- Core-Shell Scalability and Portability

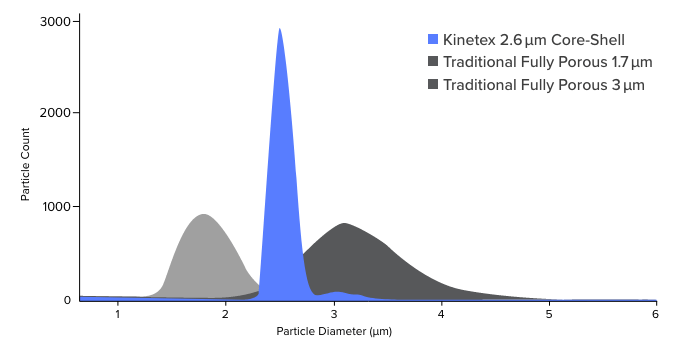

Kinetex particles are characterized by an exceptionally consistent size distribution, with particles being nearly monodispersed, meaning they are uniform in size. This precise uniformity plays a crucial role in minimizing variability within the column, leading to enhanced separation efficiency and sharper peaks.

The nearly monodispersed nature of these particles ensures that the flow of the mobile phase remains consistent, reducing the likelihood of irregularities that can impact results. As a result, Kinetex columns deliver highly reliable and reproducible performance, making them ideal for achieving consistent analytical outcomes across various applications.

Kinetex Polar C18

Minimized Band Broadening

Fully Porous

Increased Band Broadening

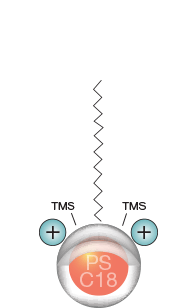

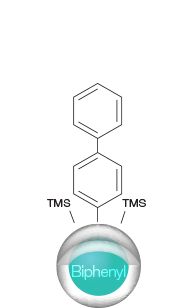

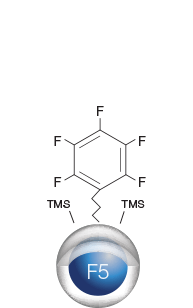

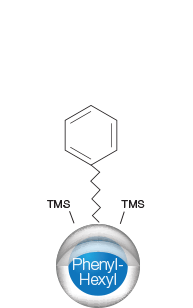

Expand Your Core-Shell Selectivity Toolbox

Kinetex core-shell particle LC columns deliver exceptional performance enhancements across any LC system, offering unmatched efficiency and resolution. With a choice of 11 diverse stationary phases, these columns cater to a wide range of chromatographic applications, ensuring optimal separation for various analytes.

Additionally, the availability of five versatile particle sizes allows for precise method tailoring, enabling both high-speed and high-resolution separations. Whether you're using HPLC or UHPLC systems, Kinetex columns provide the flexibility and performance needed to achieve superior analytical results.

|

Kinetex Phases

|

Shipping Solvent†

|

Particle

Sizes (µm) |

Pore

Size (Å) |

Surface

Area (m2/g) |

Carbon

Load (%) |

pH Stability

|

Reversed

Phase |

Normal

Phase |

HILIC

|

100%

Aqueous Stable |

|---|---|---|---|---|---|---|---|---|---|---|

|

Acetonitrile / Water (50:50)

|

2.6

|

100

|

200

|

9

|

1.5-8.5*

|

|

|

|||

|

Acetonitrile / Water (50:50)

|

2.6

|

100

|

200

|

9

|

1.5-8.5*

|

|

|

|||

|

Acetonitrile / Water (50:50)

|

1.3, 1.7, 2.6, 5

|

100

|

200

|

12

|

1.5-8.5*

|

|

||||

|

Acetonitrile / Water (45:55)

|

1.7, 2.6, 5

|

100

|

200

|

11

|

1-12

|

|

|

|||

|

Acetonitrile / Water (50:50)

|

1.7, 2.6, 3.5, 5

|

100

|

200

|

10

|

1.5-8.5*

|

|

||||

|

Acetonitrile / Water (45:55)

|

1.7, 2.6, 5

|

100

|

200

|

8

|

1.5-8.5*

|

|

||||

|

Acetonitrile/Water w/

0.1 % Formic Acid (50:50) |

1.7, 2.6, 5

|

100

|

200

|

11

|

1.5-8.5*

|

|

|

|||

|

Acetonitrile / Water (45:55)

|

1.7, 2.6, 5

|

100

|

200

|

11

|

1.5-8.5*

|

|

||||

|

Acetonitrile / Water (40:60)

|

1.7, 2.6, 5

|

100

|

200

|

9

|

1.5-8.5*

|

|

|

|

||

|

Acetonitrile /

100 mM Ammonium Formate (93:7) |

1.7, 2.6, 5

|

100

|

200

|

0

|

2.0-7.5

|

|

|

|||

|

Acetonitrile / Water (65:35)

|

3.5

|

—

|

—

|

12

|

1.5-8.5*

|

|

Core-shell vs Fully Porous

High-Efficiency‚ High-Density Particle

The combination of a consistent, solid, high-density core along with proprietary column packing technologies in the Kinetex HPLC column ensures optimum bed structure and high column performance. This carefully designed core structure promotes uniform packing of the particles, which is essential for minimizing band-broadening effects that can arise from Eddy Diffusion.

The manufacturing process of Kinetex columns is tightly controlled, focusing on factors such as particle size distribution, surface and bonding homogeneity, and packing quality. This meticulous engineering leads to uniform packing and minimized band-broadening, resulting in superior separation efficiency.

Achieve Sub-2 μm Performance within HPLC Backpressure Limitations

|

Columns:

Kinetex 2.6 µm C18

Traditional 1.7 µm C18 |

|

Dimension:

50 x 2.1 mm

|

|

Mobile Phase:

Acetonitrile / Water (50:50)

|

|

Flow Rate:

0.6 mL/min

|

|

Temperature:

25 °C

|

|

Detection:

UV @ 254 nm

|

|

Instrument:

Waters® ACQUITY® UPLC®

|

|

Sample:

0.5 µL test mixture

1. Acetophenone

2. Benzene

3. Toluene

4. Naphthalene

|

Uniform Particle Size Distribution

Every step in the manufacturing process of Kinetex Core-Shell columns is tightly controlled for:

- Surface and bonding homogeneity

- Selectivity quality control testing

- Inertness of the base silica

- Packing quality and consistency

Batch-to-Batch Reproducibility Overlay

|

Columns:

Kinetex 2.6 µm C18

|

|

Dimension:

50 x 4.6 mm

|

|

Part No.:

00B-4462-E0

|

|

Mobile Phase:

Water / Acetonitrile (65:35)

|

|

Flow Rate:

1.0 mL/min

|

|

Temperature:

25 °C

|

|

Detection:

UV @ 254 nm

|

|

Sample:

1. Uracil

2. Hydrocortisone

3. Cortisone

4. Cortisone acetate

5. 17-Hydroxyprogesterone

|

Top 5 Pros of Kinetex Core-Shell Technology

- Productivity: Kinetex Core-Shell Technology significantly enhances method productivity with minimal effort. By simply replacing traditional, fully porous columns with Kinetex HPLC columns, users can achieve better resolution, sensitivity, and overall productivity without extensive method redevelopment. This easy switch allows for immediate improvements in chromatographic performance, making it a cost-effective upgrade to existing methods.

- PortabilityThe Kinetex Core-Shell columns are available in a range of particle sizes (1.3 µm to 5 µm), which ensures method portability across different HPLC and UHPLC systems. This scalability allows for consistent retention and selectivity across various particle sizes while accommodating different backpressure levels, making it easier to transfer methods between instruments.

- Performance Kinetex Core-Shell Technology delivers superior chromatographic efficiency compared to fully porous particles. This efficiency boost enables chromatographers to maximize the performance of their HPLC/UHPLC systems, ensuring optimal results with higher resolution and sharper peaks, even under similar method conditions.

- Phases With 11 unique phase selectivities available, Kinetex Core-Shell Technology offers unmatched versatility for method development. This wide selection of phase chemistries allows for tailored separations and simplified optimization, ensuring the best possible results for a wide range of applications.

- Pressure Kinetex Core-Shell columns provide higher efficiency at lower system backpressures compared to fully porous columns. This allows users to achieve superior chromatographic performance on conventional LC instruments without the need for ultra-high-pressure systems, making it a practical choice for routine analyses.